Seramika kapillyar bog'lovchi kapillyar Yarimo'tkazgichli qadoqlash uchun

Mahsulotni qo'llash

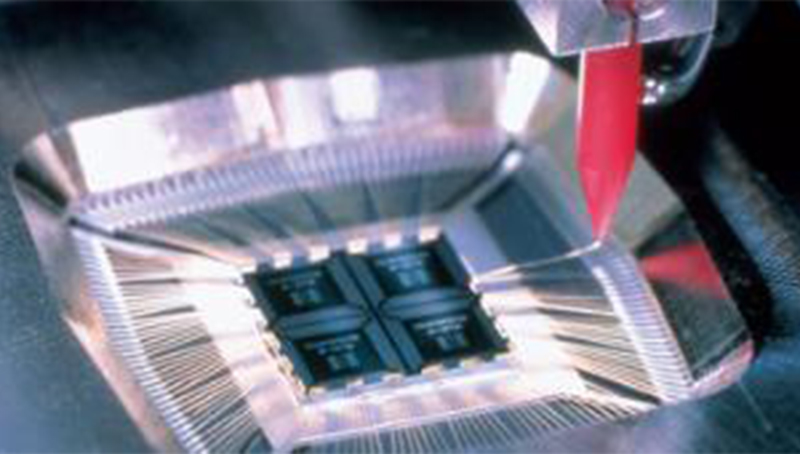

Seramika kapillyar - bu aniq mikro tuzilishli keramik komponentga tegishli bo'lgan vertikal yo'nalishda teshiklari bo'lgan ekssimetrik keramik asbob.Qo'llash nuqtai nazaridan, Seramika kapillyar simni bog'lash jarayonida simni ulash vositasi sifatida ishlatiladi.WireBonding yupqa metall simlar (mis, oltin va boshqalar) va issiqlik, bosim va ultratovush energiyasidan foydalangan holda metall qo'rg'oshinni substrat yostig'i bilan yaqindan payvand qilishi mumkin, bu esa chiplar va substratlar o'rtasidagi elektr o'zaro bog'liqligini va ular o'rtasidagi ma'lumot almashinuvini amalga oshirishi mumkin. chiplar.SCR, SAW, LED, diod, triod, IC chip va boshqa sxemalarni yopishtirish va qadoqlash uchun javob beradi.

Mahsulot afzalliklari

OPT Cutting Tools Co., LTD.Shenzhen, Guangdong, Xitoyda joylashgan.Bu ishlab chiqarish, sotish, tadqiqot va ishlanmalarni birlashtirgan kompaniya.Va chizmalar, materiallar va nostandart asboblarni loyihalash va ishlab chiqarishni o'z zimmasiga olishi mumkin.Turli xil materiallar partiyalarining barqarorligini ta'minlash uchun mahalliy birinchi ishlab chiqarish materiallarini qat'iy qabul qiling.Asboblarning sifatini ta'minlash uchun ishlab chiqarish jarayonini qat'iy nazorat qiling.Kompaniya "sifat bo'yicha omon qolish, obro'-e'tibor bilan rivojlanish" maqsadida katta texnik kuchga, kuchli ishlab chiqarish quvvatiga, ilmiy boshqaruvga ega va mijozlarga yanada yaxshi mahsulotlarni taqdim etish uchun doimo oldinga intiladi.

To'g'ri etkazib berish, yaxshi xizmat

1. OPT Cutting Tools o'zining to'liq ishlab chiqarish, ishlab chiqarish va tashish tizimiga ega.O'z vaqtida yetkazib berish.

2. Mijozlarga ko'proq mos va yaxshiroq Seramika bog'lash vositalarini yaxshiroq ta'minlash uchun mijozlar bilan birma-bir aloqa va almashinuv amalga oshirilishi mumkin

3. Mijozning maxsus talablariga muvofiq maxsus parametrlarni moslashtiring;

Birlashtiruvchi kapillyar materialni yangilash

Asl alyuminiy oksidi asosida seramika kapillyarining molekulyar strukturasini yanada ixcham qilish, yuqori qattiqlik, yaxshi aşınma qarshilik va uzoqroq xizmat qilish muddatini yaratish uchun zirkoniya, xrom oksidi va boshqalar qo'shiladi.Telni payvandlashda keramik qalam uchining eskirish va almashtirish vaqtlarini kamaytiring.

Yupqa simli bog'lovchi takozlar To'g'ri o'lcham

Kompaniyamiz barcha xarakterli o'lchamlarni qayta ishlash uchun import qilingan ishlab chiqarish uskunalarining to'liq to'plamini qabul qiladi.Yuqori aniqlikdagi ishlov berish uskunalari va boy qayta ishlash tajribasi mijozlarga qattiq o'lchamdagi mahsulotlarni taqdim etadi.

Yuqori aniqlik, yuqori o'lchamli aniqlik, kamroq ishlov berish va silliq sirt.

Mahsulot yuqori aniqlik, yuqori o'lchamli aniqlik, kamroq ishlov berish miqdori va silliq yuzaga ega.

Seramika kapillyarining tuzilishi juda aniq va murakkab bo'lib, uning asosiy o'lchamlari simni bog'lash ta'siriga katta ta'sir ko'rsatadi.OPT Cutting Tools asboblar sifatini ta'minlash uchun ishlab chiqarish jarayonini qat'iy nazorat qiladi.Mahsulotning yuqori aniqligi, yuqori o'lchamli aniqligi, kamroq ishlov berish va silliq sirtga erishish uchun.Kompaniyamiz IC qadoqlash sohasida o'rta va yuqori sifatli mahalliy keramik bog'lash vositalarini Ar-ge va ishlab chiqarishga sodiqdir.Seramika kukuni va embrion qismlari butunlay ishlab chiqilgan va mustaqil ravishda ishlab chiqariladi.

![]()

BPP: 150 mkm (mkm / mil)

| Qism NO. | WD | H | T | CD | OR | α | Θ | CA |

| A-1 | 38/1,5 | 51/2.0 | 229/9.0 | 102/4.0 | 38/1,5 | 8° | 30° | 120° |

| A-2 | 38/1,5 | 51/2.0 | 152/6.0 | 66/2.6 | 10/0,4 | 0° | 30° | 90° |

| A-3 | 38/1,5 | 51/2.0 | 229/9.0 | 86/3.4 | 102/4.0 | 0° | 30° | 90° |

| A-4 | 38/1,5 | 51/2.0 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90' |

| A-5 | 38/1,5 | 56/2.2 | 239/9.4 | 102/4.0 | 38/1,5 | 8° | 30° | 120° |

| A-6 | 38/1,5 | 56/2.2 | 229/9.0 | 96/3.8 | 102/4.0 | 0° | 30° | 90° |

| A-7 | 38/1,5 | 56/2.2 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90° |

| A-8 | 38/1,5 | 64/2,5 | 239/9.4 | 102/4.0 | 38/1,5 | 6° | 30° | 120° |

| A-9 | 38/1,5 | 64/2,5 | 203/8.0 | 89/3.5 | 61/2.4 | 0° | 30° | 90° |

| A-10 | 51/2.0 | 64/2,5 | 191/7.5 | 81/3.2 | B/0,3 | 0° | 30° | 90° |

| A-11 | 51/2.0 | 64/2,5 | 292/11.5 | 102/4.0 | 127/5.0 | 0° | 30° | 90° |

| A-12 | 51/2.0 | 76/3.0 | 356/14.0 | 122/4.8 | 152/6.0 | 0° | 30° | 90° |

| A-13 | 51/2.0 | 89/3.5 | 419/16.5 | 135/5.3 | 178/7.0 | 0° | 30° | 90° |

| A-14 | 51.64/2.0.2.5 | 76/3.0 | 330/13.0 | 140/5,5 | 64/2,5 | 8° | 30° | 120° |

| A-15 | 64.76/2.5.3.0 | 89/3.5 | 330/13.0 | 127/5.0 | 64/2,5 | 8° | 30° | 120° |

| A-16 | 64.76/2.5.3.0 | 102/4.0 | 330/13.0 | 140/5,5 | 64/2,5 | 8° | 30° | 120° |

| A-17 | 76/3.0 | 102/4.0 | 483/19.0 | 168/6.6 | 203/8.0 | 0° | 30° | 90° |

BPP: 140 mkm (mkm / mil)

| Qism NO. | WD | H | T | CD | OR | α | Θ | CA |

| B-1 | 22/0.9 | 33/1.3 | 140/5,5 | 64/2,5 | 20/0,8 | 8° | 30° | 120° |

| B-2 | 25/1.0 | 38/1,5 | 165/6,5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-3 | 25/1.0 | 38/1,5 | 89/3.5 | 53/2.1 | B/0,3 | 0° | 30° | 90° |

| B-4 | 25/1.0 | 38/1,5 | 114/4,5 | 53/2.1 | 8/0,3 | 0° | 30° | 90° |

| B-5 | 25/1.0 | 38/1,5 | 178/7.0 | 64/2,5 | 76/3.0 | 0° | 30° | 90° |

| B-6 | 25/1.0 | 38/1,5 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-7 | 25/1.0 | 43/1,7 | 165/6,5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-8 | 25/1.0 | 43/1,7 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-9 | 25.30/1.0.1.2 | 43/1,7 | 229/9.0 | 74/2.9 | 30/1.2 | 8° | 30° | 120° |

| B-10 | 25.30/1.0.1.2 | 43/1,7 | 152/6.0 | 59/2.3 | B/0,3 | 8° | 30° | 120° |

| B-11 | 25.30/1.0.1.2 | 43/1,7 | 203/8.0 | 74/2.9 | 89/3.5 | 0° | 30° | 90° |

| B-12 | 25.30/1.0.1.2 | 46/1.8 | 229/9.0 | 74/2.9 | 38/1,5 | 8° | 30° | 120° |

| B-13 | 30/1.2 | 46/1.8 | 203/8.0 | 76/3.0 | 89/3.5 | 0° | 30° | 90° |

BPP: 100 mkm(mkm/mil)

| Qism NO. | WD | H | T | CD | OR | a | Θ | CA |

| C-1 | 25/1.0 | 38/1,5 | 130/5.1 | 53/2.1 | 30/1.2 | 11 | 30° | 90° |

| C-2 | 30/1.2 | 38/1,5 | 130/5.1 | 56/2.2 | 30/1.2 | 11 | 30° | 90° |

| C-3 | 30/1.2 | 38/1,5 | 130/5.1 | 56/2.2 | 30/1.2 | 8' | 30° | 90° |

| C-4 | 30/1.2 | 38/1,5 | 130/5.1 | 56/2.2 | 30/1.2 | 4′ | 30° | 90° |

| C-5 | 30/1.2 | 41/1.6 | 130/5.1 | 59/2.3 | 30/1.2 | 11 | 30° | 90° |

BPP: 90 mkm(mkm/mil)

| Qism NO. | WD | H | T | CD | OR | α | Θ | CA |

| D-1 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0,5 | 11° | 30° | 90° |

| D-2 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0,5 | 8° | 30° | 90° |

| D-3 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0,5 | 4° | 30° | 90° |

| D-4 | 25/1.0 | 35/1.4 | 109/4.3 | 51/2.0 | 20/0,8 | 11° | 30° | 90° |

| D-5 | 30/1.2 | 38/1,5 | 109/4.3 | 51/2.0 | 20/0,8 | 11° | 30° | 90° |

| D-6 | 30/1.2 | 38/1,5 | 109/4.3 | 53/2.1 | 1310.5 | 8° | 30° | 90° |

| D-7 | 30/1.2 | 38/1,5 | 109/4.3 | 53/2.1 | 13/0,5 | 4° | 30° | 90° |

BPP: 80 mkm(mkm/mil)

| Qism NO. | WD | H | T | CD | OR | α | Θ | CA |

| E-1 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0,5 | 4° | 30° | 90° |

| E-2 | 25/1.0 | 33/1.3 | 99/3.9 | 4B/1.9 | 13/0,5 | 8° | 30° | 90° |

| E-3 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0,5 | 11° | 30° | 90° |

| E-4 | 25/1.0 | 35/1.4 | 99/3.9 | 46/1.8 | 13/0,5 | 11° | 30° | 90° |

| E-5 | 30/1.2 | 38/1,5 | 99/3.9 | 51/2.0 | 13/0,5 | 4° | 30° | 90° |

| E-6 | 30/1.2 | 3B/1,5 | 99/3.9 | 51/2.0 | 13/0,5 | 8° | 30° | 90° |

BPP: 70 mkm(mkm/mil)

| Qism NO. | WD | H | T | CD | OR | α | Φ | CA |

| F-1 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1,7 | 10/0,4 | 8° | 30° | 90° |

| F-2 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1,7 | 10/0,4 | 4° | 30' | 90° |

| F-3 | 25/1.0 | 33/1.3 | 91/3.6 | 43/1,7 | 13/0,5 | 11° | 30' | 90° |

BPP: 60 mikron(mkm/mil)

| Qism NO. | WD | H | T | CD | OR | α | Φ | CA |

| G-1 | 23/0.9 | 28/1.1 | 81/3.2 | 35/1.4 | 13/0,5 | 11° | 30° | 90° |

| G-2 | 25/1.0 | 30/1.2 | 81/3.2 | 35/1.4 | 13/0,5 | 11° | 30° | 90° |